Vol. 2i- Power Cables

Well, here we are. You’ve just unwrapped your new system, which you bought to improve upon your portable Bluetooth speaker/headphone set-up/old HiFi set-up. So, you plug it all in and to test it you’re listening to some of your favourite music- songs that you know every beat of. While this certainly represents an upgrade, perhaps you aren’t entirely satisfied with the result. Could it be that this setup sounds a little bass-heavy, or presents a little bright? Maybe it lacks depth and detail, or doesn’t sound as natural as you’d like. Or perhaps this is the best sound you’ve known to date, but you’re curious whether even this can be improved upon. So, you decide to explore upgrading your system. Having decided that, though, where to begin?

Our recommendation will always be to upgrade one component at a time. Swapping it in and out with your existing component is the only way that you can be certain of the difference any cable makes to your listening experience. Having said that- and this may come as a surprise to some- at Future Shop we believe the first step to upgrading your system, and potentially one of the most important, is to address the power being fed into it. There are a lot of different metaphors and analogies out there to describe the relationship between power and the sonic performance of your system, but the one we think describes it best is thus: power is the foundation upon which your HiFi house is built. ‘Dirty’ or ‘noisy’ power is a weak foundation and will lead to shakier performance, but ‘clean’ or ‘pure’ power provides stability to your system and allows the other components to perform to the best of their abilities.

Before we go any further, we need to address what we mean when we talk about ‘noise’. ‘Noise’ is essentially the term used to describe the result of various types of interference on an electrical signal, with the most common being RFI (radio-frequency interference) and EMI (electromagnetic interference). Interference distorts electrical signals, and in the case of a sound system, this can result in muffled sound and a loss of clarity. In almost all homes, the mains outlets in every room are all part of one ring mains. Fridges, microwaves, lights, televisions, air conditioners, wifi devices- all household appliances produce ‘noise’, and this is fed back into the mains supply. Beyond that, your ring mains is subject to noise from your neighbours, which is why apartments tend to have a noisier supply than houses. By plugging your HiFi equipment directly into a mains socket, you are feeding it power that contains some degree of ‘noise’ from everything else connected to your mains supply. By allowing this noise interference into your system, you are making it impossible for your source equipment to produce a clean signal for your amp(s) and speakers. No matter how lossless your interconnects and speaker cables are, they are not designed to fix such a problem, they will simply relay this distorted signal. For that reason, we would argue that some degree of power management is imperative to be able to give a fair assessment of the performance of everything else in your system. This can come in the form of simple power cables, isolated power blocks, or power conditioners- all of which can act as filters for the mains supply.

Let us begin with power cables- probably the first step you'd take into power management- by looking at the variables that affect their performance.

Conductor materials:

Quality cables for HiFi and AV applications will, in almost every case, features conductors made from high-purity copper and/or silver. The most common conductor material for power cables is copper, and it will feature in almost every cable designed to carry a high current. Some high-end power cables will often incorporate silver, which is a more conductive material, but it is still rare to see silver used on its own for power. In most cases, silver will be used in addition to copper conductors, often with a core conductor composed of copper with silver plating or smaller silver conductors running outside it. This is because many manufacturers have realised that the higher voltages tend to travel along the outer parts of a conductor where there is the least resistance, so it may in fact be a waste of material to make the whole conductor from silver.

Conductor configuration:

There are several different ways to configure the conductors, all of them with a different purpose and application. The main variables here are: whether the conductor is solid or stranded, and the conductor gauge (thickness). A solid conductor is a wire made from one larger strand, whereas stranded cables employ many, smaller strands. While there is a difference in their relative susceptibility to corrosion, this is usually not a great concern in AV and HiFi setups; a more significant difference between solid and stranded conductors is the durability and flexibility of the cable- solid conductors are more durable, and for this reason, they may be preferable for outdoor or some wall-installation uses, while stranded cables are more flexible, so could be preferrable in more intricate installations.

Since any cable carrying current creates a magnetic field along its surface (known as the ‘skin effect’), there is the potential for strands within a cable to distort each other's signal paths, and this phenomenon is referred to as ‘strand interaction’. Solid conductors are less susceptible to this, as even if a cable features multiple solid strands they can be effectively shielded from each other, and if there is only one strand then there can be no ‘strand interaction’. Conversely, the tiny air gaps between the various strands in a stranded configuration can amplify the effect of these magnetic fields, and also allow the signal to jump between the individual strands, both of which can result in the loss of information.

Another benefit of solid conductors is the ability to use a lower gauge, which means a thicker strand*. The lower the gauge, or the thicker the strand, the lower the resistance of the conductor and therefore the higher its capacity to carry current will be. Stranded cables must be thinner (higher gauge), which means higher resistance. To meet the same capacity as an equivalent solid conductor cable, a stranded cable will need to be thicker.

All of this ultimately means that solid conductors tend to perform better, and as such higher-end cables will usually feature them.

*N.B. The way wire gauges are measured is a little confusing and seems counterintuitive. In fact, even manufacturers often get it wrong. Gauge is measured in AWG (American Wire Gauge), with a higher AWG number meaning a thinner wire, and a lower AWG meaning a thicker wire. E.g.: 14 AWG wire is thicker than 28 AWG. This appears backwards, but this comes from the original procedure for drawing wires. The more a wire is drawn, or stretched, the thinner it becomes. The AWG number refers to how many times the wire has been drawn: therefore, the higher the number, the more it has been stretched, and the thinner it will be.

Dielectric:

A cable’s dielectric performs a number of functions: it provides structural integrity, provides some protection from interference, and minimises energy loss. The challenge faced by manufacturers is that the dielectric will absorb some electrical energy from the conductors, and then release it back to the cable. This leads to a muddling of the information passing through the conductor, and negatively affects the consistency of the signal travelling along the conductor. Better dielectrics will absorb less of this energy, and some manufacturers have even gone as far as to charge the dielectric in their cables to its maximum capacity so that it cannot absorb any further electrical energy from the conductors.

Shielding:

Audio cables are often shielded to protect them from EMI (electromagnetic interference). Many cables feature a braided shield- which is ultra-thin wires in a lattice wrapped around the dielectric- and higher-end cables will either replace or combine this with a metallic mylar foil wrapper. The effectiveness of a braided shield depends on the level of coverage it has on the wire, and while braided shields provide structural integrity, they become less flexible as coverage increases. It is also worth noting that 100% coverage is technically impossible to achieve.

Foil shields are usually made of at least two materials- one metallic and one non-conductive, with the metallic side requiring grounding through a drain wire. While they can achieve 100% coverage, they are less durable than braided shields. For maximum effect, many high-end cables will combine these two kinds of shielding to take advantage of their relative strengths and mitigate their relative weaknesses.

While shielding in power cables does protect them from external EMI, it is equally important for containing the magnetic field they produce. Where most audio cables carry a relatively low voltage and therefore do not create particularly large/strong magnetic fields, power cables carry high voltage currents and therefore create a much larger/stronger magnetic field. This is why it is recommended to route your audio cables as far away as possible from your power cables- the rest of your equipment needs to be protected from the EMI emitted from your power cables. Cheap, unshielded power cables (which you will often find in the box with your equipment) will leak EMI all around them, but higher-quality cables will have less of an impact on your other equipment.

Plugs:

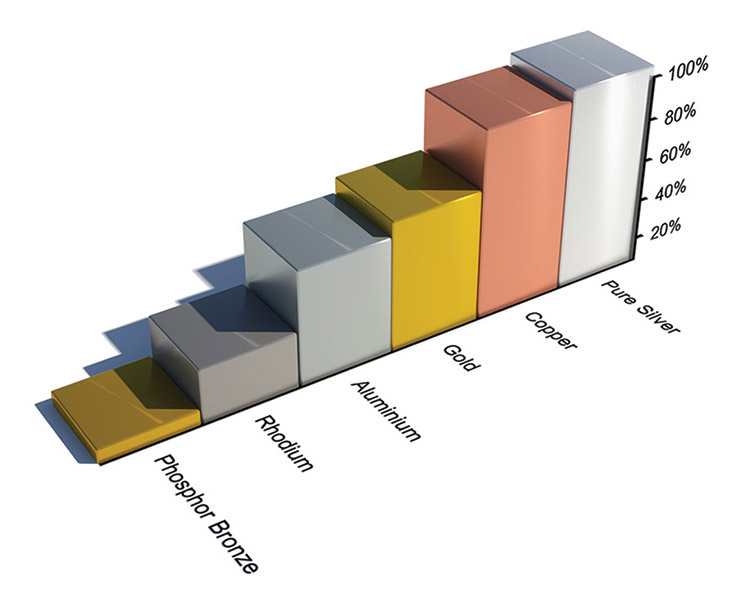

The plug connectors may not seem like particularly important factors, but if they are made from substandard materials then they can undo the work the rest of the cable does. Luckily, most manufacturers of high-quality cables will give due respect to their plugs. The best material for a plug will be a material that is equal to or better than the conductor in the cable, as the use of a different material can introduce a different resistance value. Higher quality plugs will be made of copper, whereas cheaper plugs will be made from nickel and other composite materials.

The ideal plating for your plug depends on what you value more- silver-plated terminations will be the most conductive, but will be susceptible to oxidisation over time and therefore require a level of maintenance. That is why many high-end plugs will feature gold-plated terminations- although gold is less conductive than silver, it does not oxidise, which means it has a long lifespan and requires minimal maintenance. Rhodium is an increasingly popular material used for plug plating- while it is less conductive than gold or silver it is far more durable and less susceptible to oxidisation than either of them.

It could also be worth considering the barrel or casing for the plug, as higher-quality plugs will provide better shielding for the connection point. That is why high-end power cables will often have very chunky plugs, as they contain materials to improve that shielding.

Length:

Lengths may be another variable that may not seem relevant, but there are factors to consider for each kind of cable. From a purely practical standpoint, particularly if plugging into the mains or a power block on the floor, the connection on your equipment will often be a foot or more higher than the source. Many of the higher-end cables are thick and inflexible, and at shorter lengths are only really able to travel in a straight line. This can lead to your power cable tugging on your equipment and straining the connection, or even (in some cases that we’ve heard from customers) causing your equipment to tilt backwards!

The reason that many manufacturers recommend a minimum length of 1.8 metres, however, is down to the actual performance of the power cable. Since high-quality power cables act as a filter, they will be more effective at filtering if they are given enough length to do so. By having a cable that is too short, you will not get the benefits that you are paying a premium for. There is of course a sweet spot, so like all other audio cables you don’t want them to be too long, but anything less than 1.5m may struggle to perform to its maximum potential.

Termination:

There are three main termination methods used in most audio cables:

- Screwed connections- good connection, but the least secure due to the potential for screws to loosen over time.

- Soldered connection- very secure because the conductor and plug are welded together, but introducing different materials in the solder can affect the overall resistance.

- Crimped connection- creates an airtight seal and 360 contact between the plug and the conductors. This process is generally considered to be the superior method, but is not suitable for every conductor.

Grounding:

Every power cable consists of three components- live, neutral and earth wires. The earth cable is often neglected, but it is always subject to interference from the neighbouring live and neutral. Unless a cable deals with this in some way, there will be noise generated within the cable which will pollute the signal. It is possible to negate this effect with the arrangement of the conductors, with some manufacturers spending considerable R&D time on geometry throughout the cable.

That is a lot of information, we know, but maybe it will be helpful to refer back to when you’re trying to make sense of the technical specifications provided by manufacturers.

The next entry in our series deals with the next stages of power management, looking at power distribution blocks and power conditioners; click here to continue reading!